Our teams

of specialists offer

- We design and manufacture complete shredding lines.

- We design and manufacture devices: crushers, mills

Tel: +48 501 334 923 Email: biuro@cedrus.org.pl

Crushing constitutes one of the more important stages of preparing the raw mineral for for further processing. Before the material goes to granulator or drier must be crushed and/or milled.

For the initial crushing of the agro biomass, we offer hammer crushers (RSC), used, inter alia, for grain, rapeseed straw processin and hay and also in production process of RDF (Refuse Derived Fuel – fuel from waste).

We offer a broad range of the crushing devices (crushers, mills, hatches, ventilators, transport pipes and aspiration) which allow for reducing geometrical sizes of single particles of the material processed. Our devices are intended for crushing sawdust, wood chips, green plants, hay, straw and others and their technical parameters depend on individual needs of the client.

We offer different types of mills corresponding to varied needs of our clients. These are both wet mills allowing for obtaining the finished fraction for dryign process and mills adjusted to dry processing of the material sawdust, inter alia) eg. flail mills, ideal for obtaining fraction for granulation process.

During which the processed material is more uniform in size, which impacts drying efficiency, mills suitable for dry raw materials such as sawdust (eg. hammer mills). Our mills are equipped with controllers making them safe to work with and efficient.

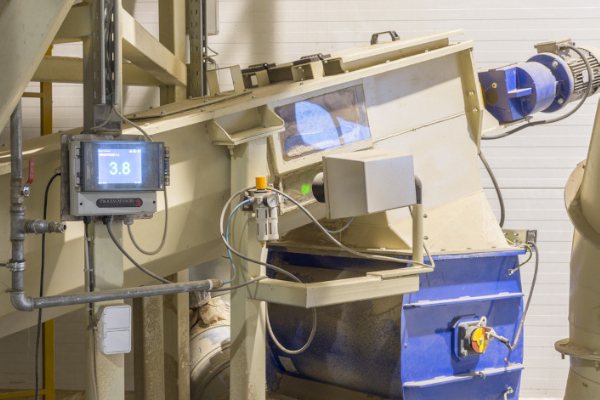

Hammer mills are extremely efficient. The design is simple and easy to operate. It’s also quick and simple to replace its parts without interrupting the operation it is performing. Our mills are equipped with the system of maintaining constant sub-pressure which reduces the risk of explosion, increases effectiveness and work safety.

Start working with us and gain a reliable partner in the development of your business. We offer innovative solutions that we will adapt to your individual needs. Thanks to experience, professionalism and modern technologies, together we will achieve success. Contact us and see how we can support your development!